Wrinkles

Influence wrinkle appearance.

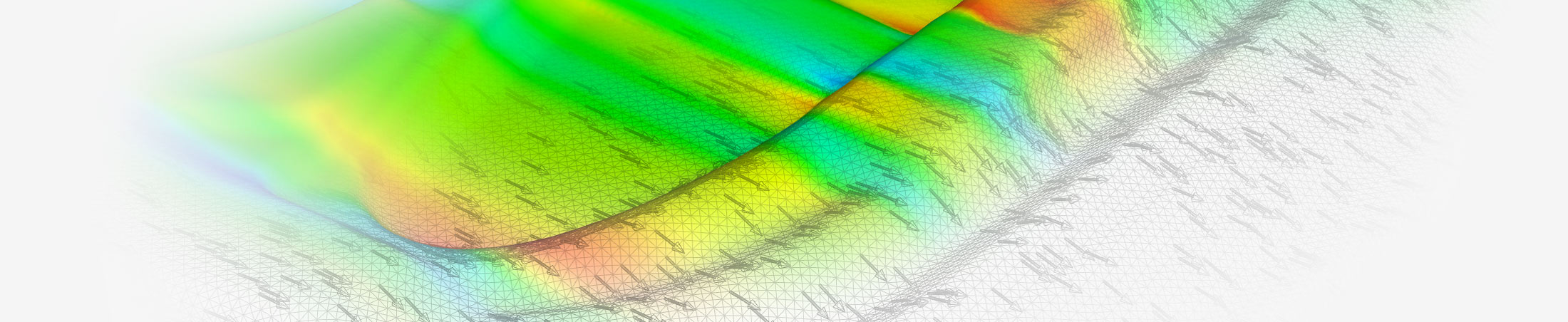

Defects such as wrinkling occur frequently, which could lead to fibre breakage leading to a knockdown of the product’s in-service performance. The local thickness increments caused by the wrinkle also result in poorly consolidated spots elsewhere in the product and possibly damage to the matched-metal tooling. Simulations can be used to optimise the process settings and the material with respect to the size and location of the wrinkles.

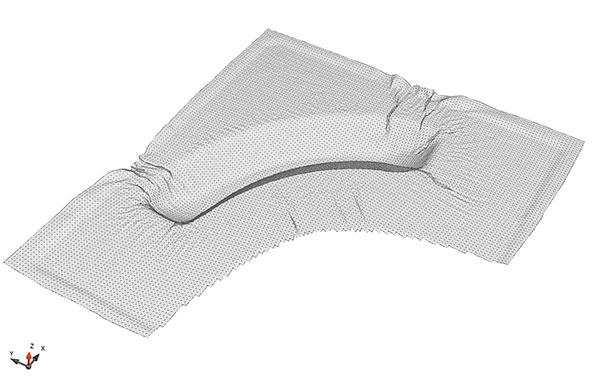

Figure 1: Predicted blank deformations for laminate plan 1, severe wrinkling.

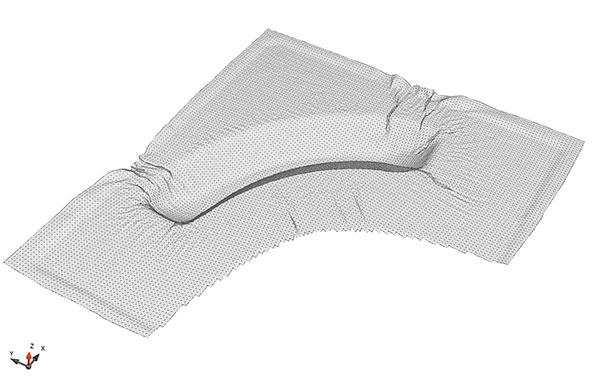

Figure 1 shows the forming of a product used in automotive industry. The development of severe wrinkling was predicted. Figure 2 shows the forming prediction of a blank with the same tooling as used in figure 1, yet with modified material parameters, thereby implicitly accounting for an increase in temperature (and therefore more compliant material properties) or the selection of another material. The modified material parameters result in a weakened potential appearance of the wrinkling.

Figure 2: Predicted blank deformations for laminate plan 2, less wrinkling.